Our Capacity

Spur Gears

Tech Specs| Pitch max | Pitch min | Ø max | Ø min | Face width max | Overall Length max |

|---|---|---|---|---|---|

| 18 Module | 0.20 Module | 1524 m/m | 1.50 m/m | 228 m/m | To application |

The most common type of gear, spur gears are mounted on parallel shafts and the edge of each tooth is straight. They are the simplest form of gear but can be noisy in mesh, and because of this are often used at low speeds or where noise is not a factor.

LMR has produced thousands and thousands of spur gears and our CNC facility enables us to be extremely competitive.

Helical Gears

Tech Specs| Pitch max | Pitch min | Ø max | Ø min | Face width max | Overall Length max |

|---|---|---|---|---|---|

| 18 Module | 0.20 Module | 1524 m/m | 1.50 m/m | 228 m/m | To application |

The teeth on a helical (spiral) gear are cut at an angle so that when they mesh the mating flank of the teeth gradually roll into each other spreading the load as they rotate. They can be used in high speed applications and transmit a far greater torque than a spur gear. They also run smoother and more quietly than spurs.

LMR has tackled many complex applications in the past and is a leader in fine pitch crossed helical gear sets, which are used in many situations as diverse as medical and marine instrumentation.

Bevel Gears

Tech Specs| Pitch max | Pitch min | Ø max | Ø min | Face width max | Overall Length max |

|---|---|---|---|---|---|

| 8 Module | To application | 565 m/m @ 10:1 ratio | To application | To application | To application |

Bevel gears are generally conical in shape and the teeth can be straight, spiral or hypoid. Their common use can be found in differential drives. This allows separate axles to rotate at different speeds depending on the ratio of gears used. They are commonly mounted on shafts to run at 90 degrees. There are various gear systems, the most common is the Gleason which is used at LMR.

LMR has extensive knowledge within this area which enables us to prepare summaries from damaged or worn samples. Our inspection facility allows us to duplicate the original function, ratio and mounting distances of the gears.

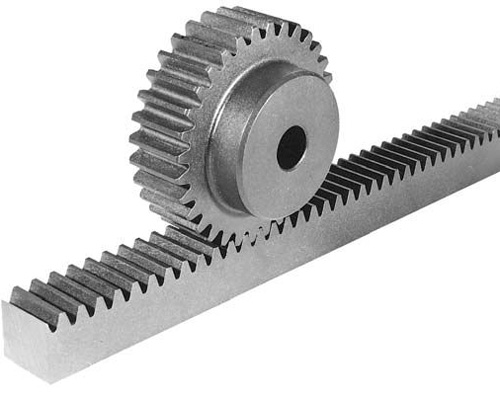

Racks and pinions

Tech Specs| Pitch max | Pitch min | Ø max | Ø min | Face width max | Overall Length max |

|---|---|---|---|---|---|

| 6 Module | 0.25 Module | N.A | N.A | 60 m/m | To application |

A rack is a straight or flat gear, and is used with a gear pinion. (See Spur Gears). If one was to take a circumference of a round gear, unfold it, then lay it flat it would be a rack. A rack and pinion produces a linear movement in any plane. If the rack is fixed and the pinion rotates whatever is attached to the pinion will drive along the rack.

LMR can cut racks onto most sections of material and has designated plant for this process. Long sections of Rack can be joined together by feeding the material through the machine.

Sprocket gears

Tech Specs| Pitch max | Pitch min | Ø max | Ø min | Face width max | Overall Length max |

|---|---|---|---|---|---|

| 50 m/m | 3.0 m/m | 1524 m/m | 5.00 m/m | To application | To application |

A Sprocket is a wheel with profiled teeth machined around its circumference that mesh with a chain or a track. They do not mesh together directly but are driven normally by a chain of the same pitch and roller diameter. They are commonly found on bicycles, motorcycles or any machinery that requires transmitting rotary motion between two shafts where gears are unsuitable for their use.

LMR produces a vast number of sprockets mainly for the marine industry where they are extensively used. The company has the benefit of CNC controlled Rigid Hobbers that give us a very competitive profile in this Industry.

Splines

Tech Specs| Pitch max | Pitch min | Ø max | Ø min | Face width max | Overall Length max |

|---|---|---|---|---|---|

| To application | To application | 1524 m/m | 5.00 m/m | To application | To application |

Splines are used as a drive mechanism or in a mechanical or electrical coupling arrangement. They transmit torque from one part to another. There are many types of splines such as Involute, Straight sided or Serrated just to name a few. External Splines are mainly milled, hobbed or shaped.

LMR has within its capacity a vast stock of both internal and external cutters and has the benefit of vertical pull broaching machines.

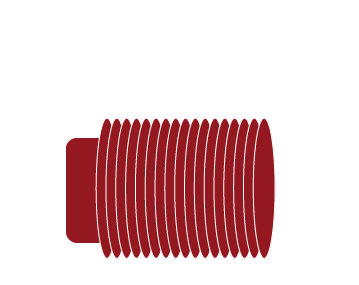

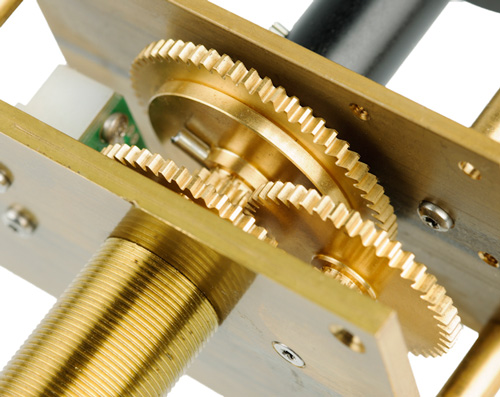

Worm gears

Tech Specs| Pitch max | Pitch min | Ø max | Ø min | Face width max | Overall Length max |

|---|---|---|---|---|---|

| 6 Module | 0.50 Module | 200 m/m | 3.00 m/m | To application | To application |

Worm gearing can reduce the rotational speed or allow higher torque to be transmitted, they are a compact way of achieving this. The addition of a worm drive to a small high-speed motor increases the range of applications that it is suitable for. The worm acts as a screw, the form on the mating wormwheel is similar in appearance to a spur gear but has a lead angle the same as the screw (worm).

A single start worm, once engaged with its wheel, rotating through 360 degrees only advances the wormwheel by one tooth, therefore a single start worm running with a 50 tooth wheel creates a ratio of 50:1

Timing Pulleys

Tech Specs| Pitch max | Pitch min | Ø max | Ø min | Face width max | Overall Length max |

|---|---|---|---|---|---|

| To application | To application | 1524 m/m | 3.00 m/m | To application | To application |

Timing Pulleys transmit power and speed in the same way as that of a chain sprocket. A Timing drive provides a non-slip synchronous transmission with less noise than a chain drive. They do not normally require any lubrication. Timing Pulleys have teeth located around their outside diameter in a radial pattern.

At LMR we have many years experience in providing timing pulleys to customers for in a variety of different sectors including Military, Automotive and the Packaging industries.

Bespoke Gears

LMR offer a bespoke service in a variety of applications. We will work with the total involvement of the end user to ensure a product that is individually tailored to your specific requirements. We appreciate that time scales are very important, to this aim LMR has an approved set of tooling manufactures being able in most cases to turn hobs and special cutters round in 2-3 weeks.

LMR can help identify your needs and requirements, especially if the item you are trying to replace is alien to you, phone and we will do our very best to help.

Emergency Service

LMR Geartech is a gear manufacturer offers an emergency service. In an emergency our expert team are just a phone call away. We offer a 24-hour breakdown service. What does this mean? Once the budget cost is agreed LMR will work, if necessary 24 hours non-stop until the item is complete. It would use its own transport facilities to obtain materials and to carry out any process operations thus reducing transit delays. We will keep the customer totally informed with the progress of the work and provide outside hours telephone numbers should they be required.